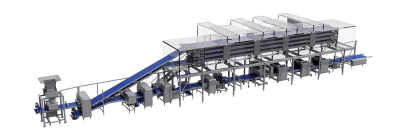

Automatic Pizza Forming Line – Optimizing Efficiency

-

Hengjiang Intelligent Technology Co., Ltd. proudly introduces the Automatic Pizza Forming Line, a state-of-the-art solution designed for high-speed, high-quality pizza production. This innovative production line is ideal for large-scale pizza manufacturers, commercial pizzerias, and frozen pizza producers, offering exceptional speed, precision, and versatility. The Automatic Pizza Forming Line integrates cutting-edge technology to streamline pizza production processes, minimize waste, and ensure consistent product quality. Whether you're making large volumes of pizzas for retail or small, custom batches for specialty orders, this system provides the ideal solution for your production needs.

High-Speed Performance with Consistent Quality

The Automatic Pizza Forming Line is designed for businesses that require high throughput and efficiency. Capable of producing pizzas at high speeds, this system ensures rapid processing without compromising on quality. Whether you are manufacturing frozen pizzas for global distribution or preparing fresh pizzas for local customers, the Automatic Pizza Forming Line provides the high-speed performance needed to meet growing demand.

Despite its high-speed capabilities, the system maintains outstanding stability, ensuring that each pizza is formed with precision and consistency. This balance of speed and quality is vital in a fast-paced production environment where meeting deadlines while maintaining product standards is key to success.

Precision Engineering for Consistent Results

Precision is at the heart of the Automatic Pizza Forming Line. The system is designed to ensure that every pizza is produced with uniformity in size, shape, and thickness. Whether producing thin-crust, thick-crust, or specialty pizzas, the advanced dough handling technology guarantees that the dough is perfectly stretched and formed for optimal cooking and texture.

This high level of precision reduces dough waste and enhances production efficiency. By ensuring that each pizza has the ideal amount of dough, businesses can reduce ingredient costs, minimize product variability, and maintain a high standard of quality. The uniformity of the pizzas also ensures even baking, delivering a consistent final product that meets customer expectations.

Versatile Production for Various Pizza Sizes and Styles

Flexibility is one of the key features of the Automatic Pizza Forming Line. This system is adaptable to different pizza sizes, allowing you to produce pizzas ranging from small individual-sized portions to large family-sized pies. It also offers versatility in terms of pizza shapes, accommodating round, square, and even custom shapes, making it ideal for businesses that want to diversify their product offerings.

The Automatic Pizza Forming Line also supports various crust styles, including traditional, thin, and thick crusts, allowing manufacturers to cater to diverse consumer preferences. Whether your business specializes in classic pizzas or is exploring new crust types, the system can easily be adjusted to produce different pizza styles with minimal setup time.

Additionally, the system can handle different dough types, including gluten-free, whole grain, and other specialty doughs, helping businesses meet the growing demand for dietary-specific options. This versatility makes the Automatic Pizza Forming Line an invaluable asset for businesses looking to innovate and expand their product range.

Hygienic and Safe Design for Food Production

Food safety and hygiene are essential considerations in pizza production, and the Automatic Pizza Forming Line is built with these priorities in mind. Constructed from high-quality, food-grade materials, the system features a smooth, seamless design that prevents dough buildup and contamination, ensuring a safe and hygienic production environment.

The system also includes an automated cleaning function, which allows for quick and efficient sanitization between production runs. This automated cleaning feature reduces downtime and ensures that the production line remains sanitary, meeting food safety standards and regulations. By maintaining a clean environment, the Automatic Pizza Forming Line helps businesses avoid contamination risks and enhance product quality.

Easy Operation and Low Maintenance

The Automatic Pizza Forming Line is designed with user-friendliness in mind. The intuitive control panel makes it easy for operators to monitor and adjust settings with minimal training. With automated functions that reduce manual intervention, the system increases production efficiency and reduces the risk of human error.

The system is also built for low maintenance, ensuring minimal downtime and long-term reliability. Its durable components and automated features reduce the need for constant supervision and repairs, allowing businesses to focus on scaling their operations without worrying about frequent maintenance issues.

Scalability to Meet Growing Demands

As businesses expand, the Automatic Pizza Forming Line can easily scale to accommodate increasing production demands. Its modular design allows businesses to add more components or increase output capacity as needed. Whether you're ramping up production for peak seasons or diversifying your product lineup, the system can be customized to meet your evolving needs, ensuring that your production line grows with your business.

Conclusion

The Automatic Pizza Forming Line from Hengjiang Intelligent Technology Co., Ltd. is an ideal solution for businesses looking to optimize their pizza production processes. With its high-speed performance, precision engineering, versatility in size and style, and hygienic design, this system is built to enhance operational efficiency, reduce waste, and produce high-quality pizzas consistently.

Whether you're a large-scale manufacturer or a smaller pizzeria looking to improve your production capacity, the Automatic Pizza Forming Line offers the flexibility and reliability you need to stay competitive in the fast-paced pizza industry. By integrating this advanced production line into your operations, you can ensure a smooth, efficient process that consistently delivers top-quality pizzas to your customers.