Categories

Tags

-

#Agricultural High Pressure Spray Nozzle

#Industrial Needs

#Crystal Glass Pendant

#Blush Manufacturer

#Air Purifier Fan

#leather sewing machine spare parts

#Jojo Magnet Paper

#cemented carbide tips

#Deep Fryer 3L

#Multifunction socket

#Spring Check Valve

#Frying Pan Factory

#Non-Stick Frying Pan Supplier

#Axial Flow Fan Manufacturer

#External Rotor Axial Fan

#Plumbing Pipe Crimping Tool

#Hydraulic Crimping Tool

#Halloween Makeup Kit

#Party Body Glitter

#Battery Pipe Expander

#Battery Pipe Plumbing Tool

#Smart Door

#Printing Machine Sensor

#Carton Close Staple

#LED Christmas Curtain Lights

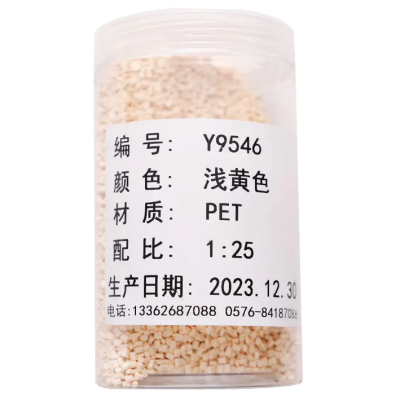

#Injection Color Masterbatch

#PlasticMasterbatchManufacturer

#Cat Delivery Room

#Oil Pipeline Valve

#Nail Polish

#Watercolor Pen

#Macaron Color Watercolor Pen

#High And Low Voltage Isolation Switch

#Manual Pipe Cutting Machine

#Metal stud

#Beverage Pearlescent Film Label

#PLA Compostable Takeaway Containers

#Kawaii Erasers

#Cast Iron Frying Pan

#Pearlescent Color Masterbatch

#Hydraulic clutch release bearing

#Oriental Rugs

Archives

How Visual Quality Quietly Shapes Product Trust

-

You notice it at the end of a long production run. The parts look fine—until you line them up under the same light. Slight differences. A tone that feels “off.” Not enough to stop shipment, but enough to trigger doubt. This is where conversations around Injection Color Masterbatch and Pearlescent Color Masterbatch often begin, even if manufacturers don’t realize it yet.

For many brands, color inconsistency has become a tolerated frustration. Adjustments during production, extra sampling, small compromises in appearance—all accepted as part of the process. The problem is that today’s customers notice more than ever. On social media, under studio lighting, or in unboxing videos, visual flaws are amplified. What once passed as acceptable now quietly damages brand perception.

The real pain isn’t just the mismatch. It’s the time spent correcting it. Operators tweak settings. Teams debate whether a batch is “close enough.” Production slows, not dramatically, but enough to feel it. This is the gap many manufacturers live with without realizing there’s a smoother way.

A well-formulated Injection Color Masterbatch changes this rhythm. Instead of constant micro-adjustments, color becomes predictable. Operators focus on molding, not chasing tone. The workflow stays the same, but the mental load drops. That sense of “we’ll fix it later” disappears.

When visual differentiation matters—especially in consumer goods—Pearlescent Color Masterbatch introduces another layer of control. Instead of relying on surface finishes or post-processing to create appeal, the material itself carries the visual story. Subtle shimmer, depth, and consistency appear naturally, even across long runs.

What makes this shift powerful is that it doesn’t demand new habits. Feeding methods remain familiar. Processing feels unchanged. Yet the output feels elevated. Fewer rejected parts. Fewer internal debates. More confidence when products leave the line.

In a market where customers judge products before they ever touch them, color is no longer decoration—it’s communication. And when color stops being a problem to manage, manufacturers finally get to focus on what really moves their business forward.